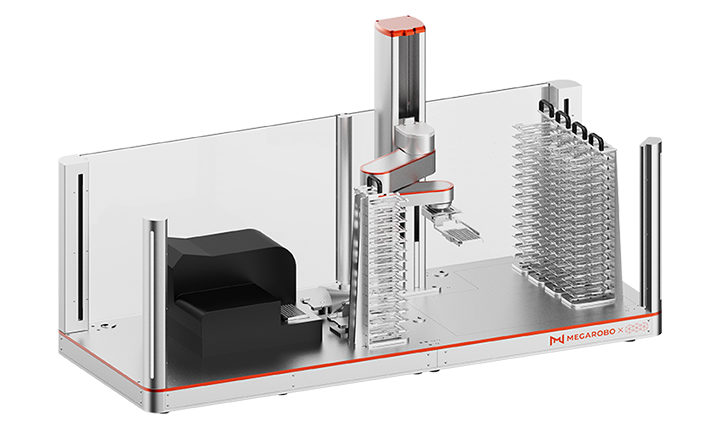

Automated Film Peeler/Sealer Series

Automated Film Peeler/Sealer Series

The equipment is used in the reliable automatic heat sealing process of sheet film, equipped with film positioning column.

Product introduction

-

MRA-AFS-100

-

MRA-AFS-200

-

MRA-AFS-201

-

MRA-AFS-300

Automated Film Sealer

MRA-AFS-100

Product Features

It is suitable for sealed storage of heat-sensitive substances, such as biochemical reagents, proteases, antibodies, PCR reagents, etc.

It can be integrated into automation systems.

It is suitable for aluminum film, high permeability film, lightproof film and other sealing films.

The system can automatically recognize shallow well, deep well, PCR and other

plates with various heights for reliable film sealing.

The adhesive film adheres to the plate by pressure, avoiding various problems

caused due to thermal effects or weak adhesion between the plate and the film.

It only takes 8s for the whole sealing process.

It is applicable to the USB or RS232 interface, and also can be controlled via the

TTL signal wire

It has a small footprint, with a bottom area of only 255mm x 240mm.

Application scenarios

-

ELISA

-

PCR set up

-

Crystallization experiment

-

Microbial cultivation

-

Sealing of biochemical reagents

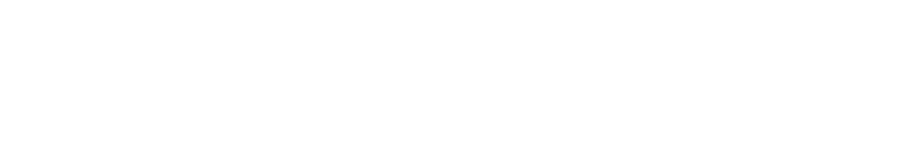

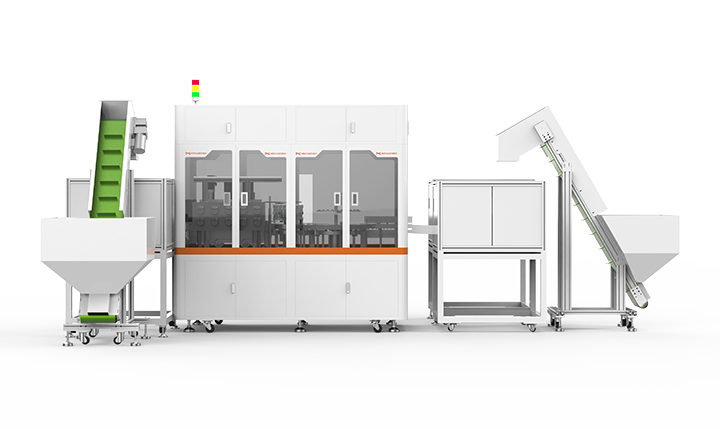

Automated Film Heat Sealer

MRA-AFS-200

Product Features

It can be applied to the automatic film sealing process of well plates conforming to SBS standard.

It has good flexibility and can be sealed by roll film/sheet film.

Its sealing film temperature can be adjusted from 100 ℃ to 200 ℃.

Manual/automatic modes can be switched.

The heat sealing effect is reliable, and the whole film sealing process only takes 10-15 seconds.

It has high stability and can work continuously for 24 hours.

It has a small footprint, with a bottom area of only 300mm x 350mm, without compressor air pump.

It is equipped with an automatic well plate tray which can be automatically raised for easy removal.

It can integrated into the automation system .

Application scenarios

-

IVD kit production

-

PCR set up

-

Sealing of biochemical reagents

-

Sealing film of other SBS plates

Automated Film Heat Sealer

MRA-AFS-201

It can be applied to the automatic film sealing process of well plates conforming to SBS standard.

It can be applied to the operation of 8-Tube Strip gland.

It is suitable for a variety of sealing films and different application requirements.

It only needs to place the film on the well plate and seal the film with one key.

The heat sealing effect is reliable, and the whole film sealing process only takes 10-15 seconds.

It has high stability and can work continuously for 24 hours.

It has a small footprint, with a bottom area of only 430mm x 200mm, without compressor air pump.

Wide range of application temperature, stable film sealing from room temperature to 250 ℃.

It is equipped with film positioning column to prevent displacement during sealing.

Application scenarios

-

IVD kit production

-

PCR set up

-

Sealing of biochemical reagents

-

Sealing film of other SBS plates

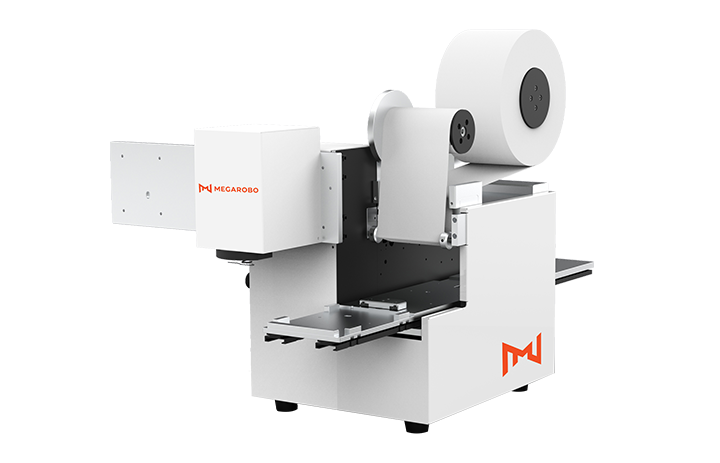

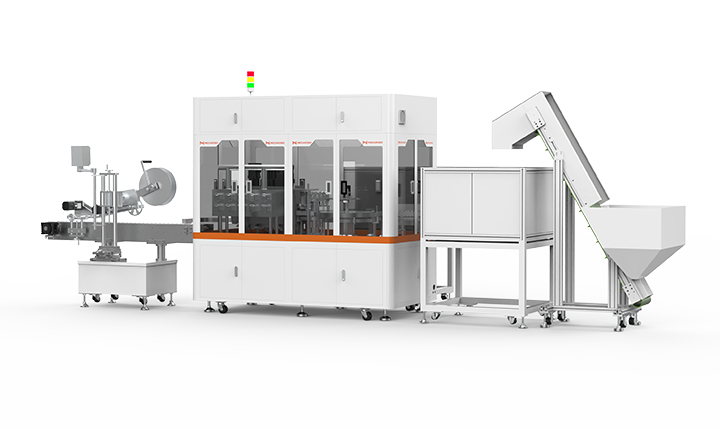

Automated Film Tearer/Sealer

MRA-AFS-300

Product Features

It can be applied to the automatic film sealing process of well plates conforming to SBS standard.

It is suitable for sealed storage of heat-sensitive substances, such as biochemical reagents, proteases, antibodies, PCR reagents, etc.

It is suitable for a variety of sealing films and different application requirements.

The system can automatically recognize shallow well, deep well, PCR and other plates with various heights for reliable film sealing.

Mechanical film tearing, no compressed air or vacuum equipment is required, and sensors detect the peeling foil and film tearing effect.

Sealing speed: 8s/plate, tearing speed: 20s/plate.

It has a small footprint, with a bottom area of only 280mm x 320mm, without compressor air pump.

It is applicable to the USB or RS232 interface, and also can be controlled via the TTL signal wire.

Friendly interface, equipped with board counter, detector and knife break diagnosis.

Application scenarios

-

ELISA

-

PCR set up

-

Crystallization experiment

-

Microbial cultivation

-

Sealing of biochemical reagents

CONTACT US

Related Products