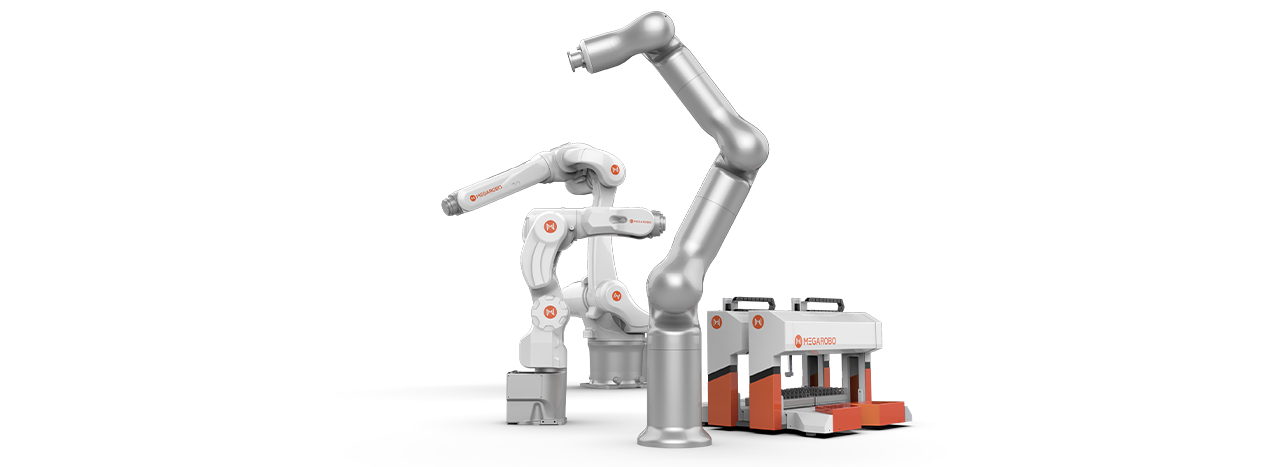

ROBOTICS

ROBOTICS

Light, safe, smart and clean robot products with different configurations, flexibly applicable to sensitive scenarios of life sciences and semiconductor manufacturing fields.

TECHNICAL ARCHITECTURE

TECHNOLOGY ADVANTAGES

CORE TECHNOLOGIES

Spinal cord and nerve of robots: MRQ series drive controller

MRQ series closed-loop multiaxis motor drive controller, independently developed by MEGAROBO, are integrated drive-controller design. Based on the CANOpen Protocol, the products have built-in axis controller and can be configured with PVT sequences, which greatly reduces users’ design cost. With a number of patented core technologies, MRQ series have abundant features of high precision, low heat generation, low noise, small size, networking, easy expanding and so on. With various input and output interfaces, MRQ series also have various control functions such as positioning, speed control, homing. Besides, MRQ series have got CNAS and CE certifications.

-

MegaSmooth

Adaptive Speed Interpolation Smoothing Technology -

MegaRobust

Full Digital Closed-loop Feedback Control Technology -

MegaSync

Bus Synchronization Technology -

MegaTuning

Motor Parameter Self-tuning Technology

MegaSmooth Adaptive Speed Interpolation Smoothing Technology

MegaSmooth Adaptive Speed Interpolation Smoothing Technology

Ensure the frequency conversion in each step and flexible motion output. Solve the problem of impact on the system posed by acceleration and deceleration in motor control. Provide a stable and vibration-free motion process. Reduce the difficulty of system design.

Trapezoidal curve interpolation

Cubic trapezoid S-curve interpolation

Quintic trapezoid S-curve interpolation

Higher order arc curve interpolation

Cubic S-curve interpolation

Quintic S-curve interpolation

MegaRobust Full Digital Closed-loop Feedback Control Technology

MegaRobust Full Digital Closed-loop Feedback Control Technology

Dynamically compensate the mechanical error of the transmission mechanism. Effectively improve the motion accuracy. Significantly reduce the system’s precision requirements of the transmission equipment manufacturing accuracy. Effectively solve the problem of system output accuracy at a lower cost. Reduce the difficulty and cost of system maintenance.

MegaSync Bus Synchronization Technology

MegaSync Bus Synchronization Technology

Control up to 100 motors in the system with one bus. Ensure the synchronization error of all motors on the bus less than 0.1μs. This technology not only provides a reliable and simple networking scheme, but also solves the problem of synchronous execution among different devices in the network. It is suitable for mechanical devices with strict synchronous accuracy requirements.

MegaTuning Motor Parameters Self-tuning Technology

MegaTuning Motor Parameters Self-tuning Technology

Effectively reduce motor heat generation and make the equipment energy-saving and environmental friendly.

Fully play to the best performance of each motor without extra configuration.

Industry applications