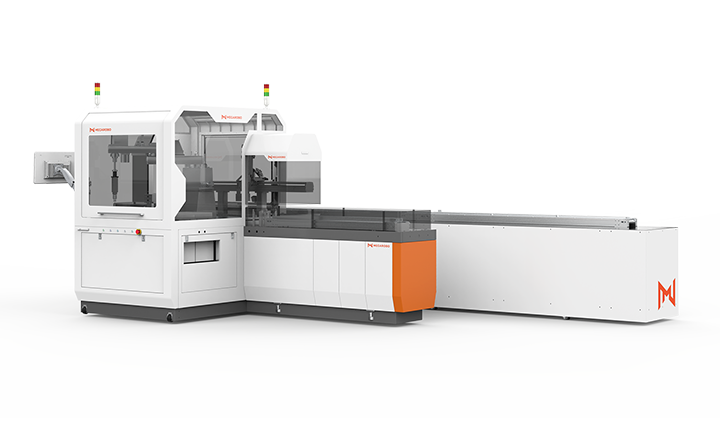

Molecular Diagnostics Reagent Filling System

Molecular Diagnosis Reagent Filling System

The series products are solutions developed for micro-filling, which can realize fully automated steps such as feeding, labeling, filling, capping, coding, and unloading.

Product introduction

-

Enzyme Reagent Pipetting Filling System

-

Large Volume Reagent Filling System

-

Pre-Packed 96-well Plate Reagent Filling and Sealing System

Application scenarios

-

High-precision micro-filling

-

Cryopreservation tube filling

-

Enzyme reagent filling

-

Nucleic acid filling

CONTACT US