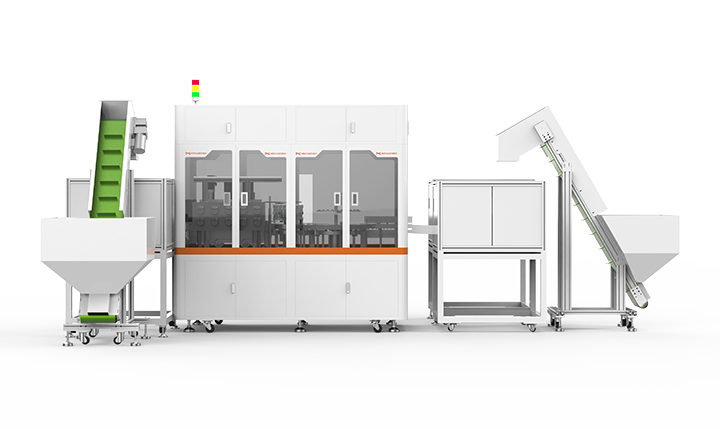

Enzyme Reagent Pipette Filling System

Fully automatic Filling system for molecular diagnostic reagents

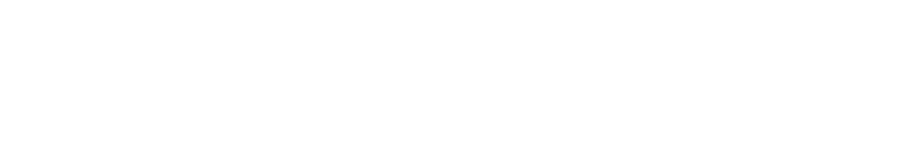

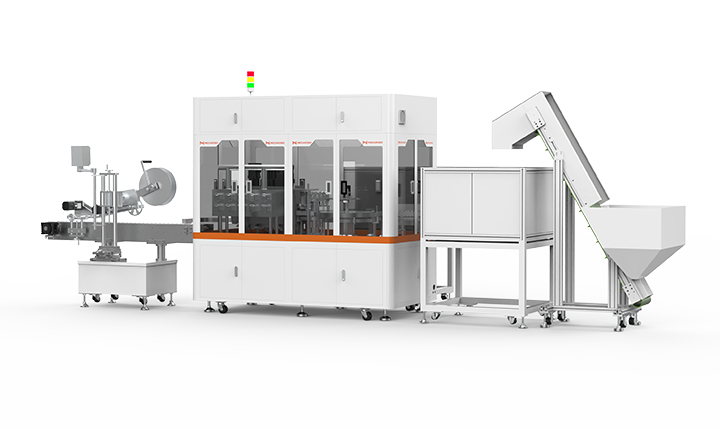

The series products of enzyme reagent pipette and filling system MRA-LSF-880 HP/HT are solutions developed for micro-filling, which can realize fully automated steps such as feeding, labeling, filling, capping, coding and unloading.

Product introduction

Enzyme Reagent Pipette Filling System

MRA-LSF-880 HP/HT

Product Features

The throughput can reach 2500 pcs/h (varies according to the properties of the reagent). Multi-step OC can detect the liquid volume, capping, labeling, coding, color of tube cap, etc.. The NG products are separately unloaded.

It supports small vertical spiral tubes of various specifications, can be filled with enzymes and water-based reagents and equipped with three-stage temperature-controlled low-temperature storage.

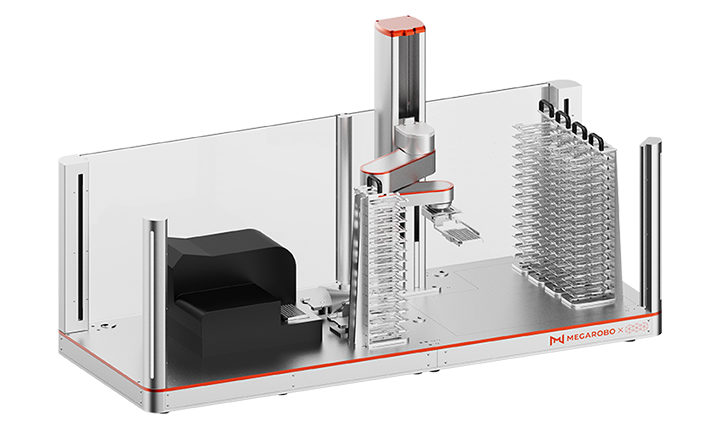

Pipetting accuracy is guaranteed. Tip head is automatically loaded and unloaded. And there is no residue in the mother liquid.

The feeding area is equipped with FFU to ensure the cleanliness of the silo. Ultraviolet disinfection with laminar flow hood is used to ensure a class 100 clean operating environment. The pipetting area is separated from the labeling and coding area to prevent the contamination of reagents by fine particles such as ink dust.

Application scenarios

-

High-precision micro-filling

-

Cryopreservation tube filling

-

Enzyme reagent filling

-

Nucleic acid filling

CONTACT US